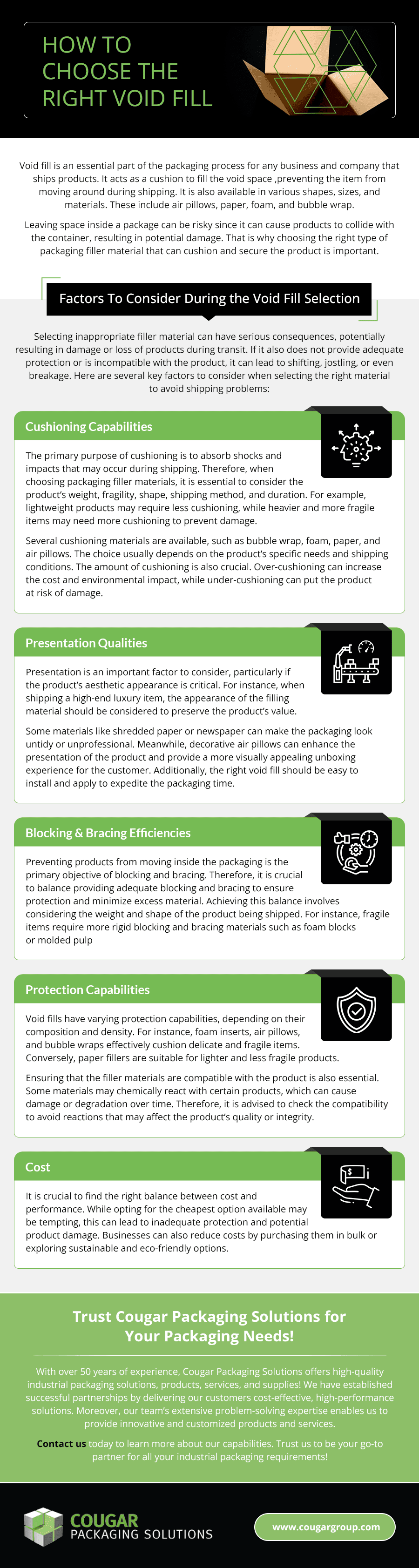

How To Choose the Right Void Fill

Void fill is an essential part of the packaging process for any business and company that ships products. It acts as a cushion to fill the void space ,preventing the item from moving around during shipping. It is also available in various shapes, sizes, and materials. These include air pillows, paper, foam, and bubble wrap.

Leaving space inside a package can be risky since it can cause products to collide with the container, resulting in potential damage. That is why choosing the right type of packaging filler material that can cushion and secure the product is important. In this article, we will present key factors to consider when selecting the right type of void fill for your application.

Factors To Consider During the Void Fill Selection

Selecting inappropriate filler material can have serious consequences, potentially resulting in damage or loss of products during transit. If it also does not provide adequate protection or is incompatible with the product, it can lead to shifting, jostling, or even breakage. Here are several key factors to consider when selecting the right material to avoid shipping problems:

Cushioning Capabilities

The primary purpose of cushioning is to absorb shocks and impacts that may occur during shipping. Therefore, when choosing packaging filler materials, it is essential to consider the product’s weight, fragility, shape, shipping method, and duration. For example, lightweight products may require less cushioning, while heavier and more fragile items may need more cushioning to prevent damage.

Several cushioning materials are available, such as bubble wrap, foam, paper, and air pillows. The choice usually depends on the product’s specific needs and shipping conditions. The amount of cushioning is also crucial. Over-cushioning can increase the cost and environmental impact, while under-cushioning can put the product at risk of damage.

Presentation Qualities

Presentation is an important factor to consider, particularly if the product’s aesthetic appearance is critical. For instance, when shipping a high-end luxury item, the appearance of the filling material should be considered to preserve the product’s value.

Some materials like shredded paper or newspaper can make the packaging look untidy or unprofessional. Meanwhile, decorative air pillows can enhance the presentation of the product and provide a more visually appealing unboxing experience for the customer. Additionally, the right void fill should be easy to install and apply to expedite the packaging time.

Blocking and Bracing Efficiencies

Preventing products from moving inside the packaging is the primary objective of blocking and bracing. Therefore, it is crucial to balance providing adequate blocking and bracing to ensure protection and minimize excess material. Achieving this balance involves considering the weight and shape of the product being shipped. For instance, fragile items require more rigid blocking and bracing materials such as foam blocks or molded pulp.

Protection Capabilities

Void fills have varying protection capabilities, depending on their composition and density. For instance, foam inserts, air pillows, and bubble wraps effectively cushion delicate and fragile items. Conversely, paper fillers are suitable for lighter and less fragile products.

Ensuring that the filler materials are compatible with the product is also essential. Some materials may chemically react with certain products, which can cause damage or degradation over time. Therefore, it is advised to check the compatibility to avoid reactions that may affect the product’s quality or integrity.

Cost

It is crucial to find the right balance between cost and performance. While opting for the cheapest option available may be tempting, this can lead to inadequate protection and potential product damage. Businesses can also reduce costs by purchasing them in bulk or exploring sustainable and eco-friendly options.

Trust Cougar Packaging Solutions for Your Packaging Needs!

With over 50 years of experience, Cougar Packaging Solutions offers high-quality industrial packaging solutions, products, services, and supplies! We have established successful partnerships by delivering our customers cost-effective, high-performance solutions. Moreover, our team’s extensive problem-solving expertise enables us to provide innovative and customized products and services.

Contact us today to learn more about our capabilities. Trust us to be your go-to partner for all your industrial packaging requirements!