What You Don’t Know About Shrink Wrap

Leave a Comment

Consumers expect products and their packaging to be intact and protected from tampering, contamination, weather, dust, and other hazards. Shrink wrapping is one of the easiest, fastest, and most cost-effective ways to achieve these goals. Whether it’s protecting individual products, bundling multiple products together, or both, heat shrink wrap can maintain product and packaging integrity while improving customer satisfaction and simplifying tasks for retailers.

There are two main types of shrink wrapping: shrink bundling with polyethylene film and shrink wrapping with polyolefin film. Shrink bundling creates bullseyes on the ends of the product(s) for easy handling, while shrink wrapping creates a complete seal around the product(s). Here we’ll talk about both types generally as shrink wrapping, explaining the process, advantages, and applications of this simple but effective packaging method.

What Is Shrink Wrap?

The shrink wrapping process involves briefly applying heat to one or more products wrapped in polyolefin or polyethylene film to form a close-fitting, protective layer of plastic that conforms even to oddly-shaped items (but not sharp objects). Versatile and FDA-approved for food-safe use, polyolefin shrink wrap film is clear and strong, even in very thin layers. Polyethylene shrink wrap film is a type of polyolefin available in different densities: high-density, low-density, and linear low-density. As a shrink film, polyethylene is flexible, strong, and resistant to moisture, impact, and chemicals.

With just a shrink wrap film and heat source, packagers can make nearly any product of any size weatherproof, waterproof, and tamperproof.

Shrink Wrapping Process

The shrink wrapping process is usually automated, allowing for varying speed and quality of the resulting shrink wrap. Here are the basic steps of the process:

- Group products: Products are placed in the desired formation (for example, 2 x 3 to form a 6-pack) along the packaging line. Slower machines group products within the machine, while faster machines group together pre-collated products.

- Form bundles: A bundle is formed when shrink wrap film conforms around the products. Two rolls can be used at once, with a hot knife cutting and sealing in a single step, or one roll can be overlapped and cut, leaving the sealing for the heat tunnel.

- Heat shrink wrap: Heat must be applied to the wrapped products for the shrink wrap to conform to product contours. In the heat tunnel, hot air is circulated briefly to shrink the film, followed by setting it in cooler air.

Advantages of Shrink Wrapping

Shrink wrapping offers benefits to manufacturers, retailers, transportation providers, and consumers.

Protection

Shrink wrapping offers a protective barrier between products and the environment, dramatically reducing the risk of product damage by moisture, air, dirt, dust, or abrasion. Some shrink wrapping materials also provide UV protection to prevent degradation when exposed to the sun.

Improved Durability

Shrink wrap adds resilience and strength to packaging, ensuring bundled products stay together and remain visually appealing and shelf-ready. Shrink wrap resists tears, punctures, and sagging in hot and cold ambient conditions.

Tamper-Evident Protection

Since shrink wrap can completely enclose a product without gaps or changing shape, any attempts at tampering are obvious. This is why most companies in the pharmaceutical, food, and financial industries rely on shrink wrapping to safeguard product integrity.

Affordability

Since they are lightweight and conform to products without extra bulk, shrink wrapping keeps transportation costs low. Shrink wrapping materials and processes are also fast and cost-effective, easily paying for themselves with the protection and safety they provide.

Branding

Because shrink wrap can be custom colored and printed, it offers a larger, more visible canvas to share your brand identity.

Convenience and Ease of Handling

From individual parts to large bundles of multiple products, shrink wrapping can make it easier to handle products and keep components together. Shrink bundling with polyethylene film can be done with openings—called bullseyes—on the ends, which makes bulky or oddly-shaped products like cases of bottles much easier for retailers and consumers to manage.

Shrink Wrapping Applications

While shrink wrapping can accommodate virtually any object size and shape—from tiny pieces of hardware to entire boats—most shrink wrapping applications include the following:

- Bottles, cans, jars, boxes, or cartons containing food, beverages, or other consumer goods

- Products and materials for the printing and paper converting industries

- Medical and pharmaceutical uses where safety and tamper-evident packaging are critical

- Third-party logistics and contract packaging providers

- Home improvement and construction products

Shrink Wrapping With Cougar Packaging Solutions

At Cougar Packaging Solutions, our shrink bundling and multipacking machines are designed to help you take advantage of the many benefits of shrink wrapping, saving you time, labor, and money. Backed by over 50 years of packaging experience, we are dedicated to providing efficient packaging products and services to our customers. Contact us today to learn how we can help you with your packaging needs.

What Are the Benefits of Air Pillows?

Leave a Comment

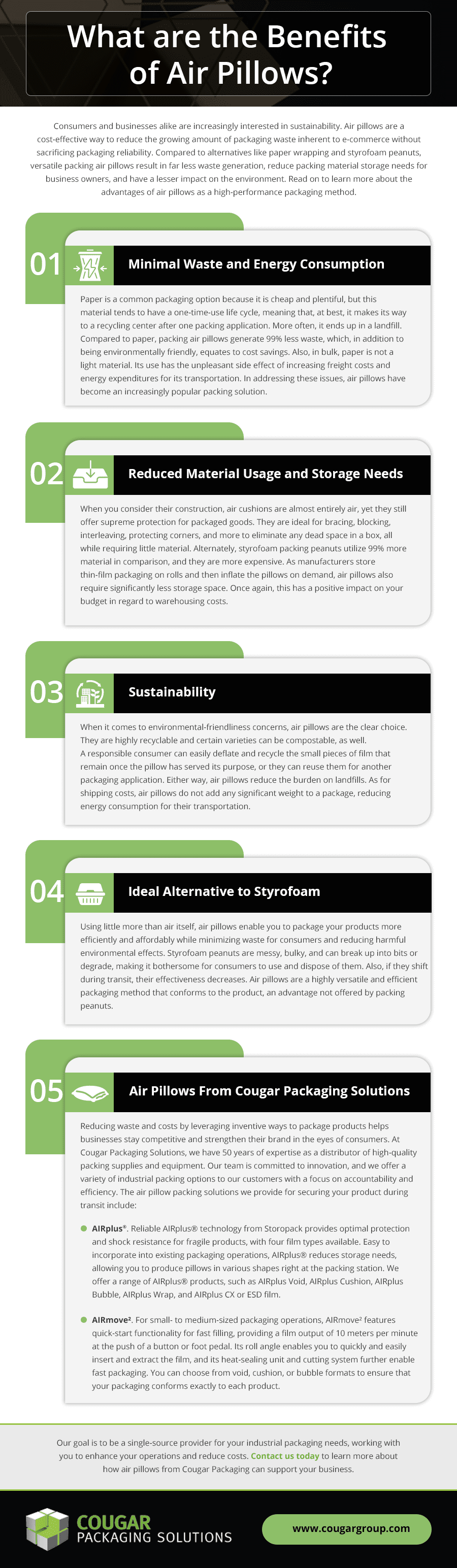

Consumers and businesses alike are increasingly interested in sustainability. Air pillows are a cost-effective way to reduce the growing amount of packaging waste inherent to e-commerce without sacrificing packaging reliability. Compared to alternatives like paper wrapping and styrofoam peanuts, versatile packing air pillows result in far less waste generation, reduce packing material storage needs for business owners, and have a lesser impact on the environment. Read on to learn more about the advantages of air pillows as a high-performance packaging method.

Minimal Waste and Energy Consumption

Paper is a common packaging option because it is cheap and plentiful, but this material tends to have a one-time-use life cycle, meaning that, at best, it makes its way to a recycling center after one packing application. More often, it ends up in a landfill. Compared to paper, packing air pillows generate 99% less waste, which, in addition to being environmentally friendly, equates to cost savings. Also, in bulk, paper is not a light material. Its use has the unpleasant side effect of increasing freight costs and energy expenditures for its transportation. In addressing these issues, air pillows have become an increasingly popular packing solution.

Reduced Material Usage and Storage Needs

When you consider their construction, air cushions are almost entirely air, yet they still offer supreme protection for packaged goods. They are ideal for bracing, blocking, interleaving, protecting corners, and more to eliminate any dead space in a box, all while requiring little material. Alternately, styrofoam packing peanuts utilize 99% more material in comparison, and they are more expensive. As manufacturers store thin-film packaging on rolls and then inflate the pillows on demand, air pillows also require significantly less storage space. Once again, this has a positive impact on your budget in regard to warehousing costs.

Sustainability

When it comes to environmental-friendliness concerns, air pillows are the clear choice. They are highly recyclable and certain varieties can be compostable, as well. A responsible consumer can easily deflate and recycle the small pieces of film that remain once the pillow has served its purpose, or they can reuse them for another packaging application. Either way, air pillows reduce the burden on landfills. As for shipping costs, air pillows do not add any significant weight to a package, reducing energy consumption for their transportation.

Ideal Alternative to Styrofoam

Using little more than air itself, air pillows enable you to package your products more efficiently and affordably while minimizing waste for consumers and reducing harmful environmental effects. Styrofoam peanuts are messy, bulky, and can break up into bits or degrade, making it bothersome for consumers to use and dispose of them. Also, if they shift during transit, their effectiveness decreases. Air pillows are a highly versatile and efficient packaging method that conforms to the product, an advantage not offered by packing peanuts.

Air Pillows From Cougar Packaging Solutions

Reducing waste and costs by leveraging inventive ways to package products helps businesses stay competitive and strengthen their brand in the eyes of consumers. At Cougar Packaging Solutions, we have 50 years of expertise as a distributor of high-quality packing supplies and equipment. Our team is committed to innovation, and we offer a variety of industrial packing options to our customers with a focus on accountability and efficiency. The air pillow packing solutions we provide for securing your product during transit include:

- AIRplus®. Reliable AIRplus® technology from Storopack provides optimal protection and shock resistance for fragile products, with four film types available. Easy to incorporate into existing packaging operations, AIRplus® reduces storage needs, allowing you to produce pillows in various shapes right at the packing station. We offer a range of AIRplus® products, such as AIRplus Void, AIRplus Cushion, AIRplus Bubble, AIRplus Wrap, and AIRplus CX or ESD film.

- AIRmove². For small- to medium-sized packaging operations, AIRmove² features quick-start functionality for fast filling, providing a film output of 10 meters per minute at the push of a button or foot pedal. Its roll angle enables you to quickly and easily insert and extract the film, and its heat-sealing unit and cutting system further enable fast packaging. You can choose from void, cushion, or bubble formats to ensure that your packaging conforms exactly to each product.

Our goal is to be a single-source provider for your industrial packaging needs, working with you to enhance your operations and reduce costs. Contact us today to learn more about how air pillows from Cougar Packaging can support your business.