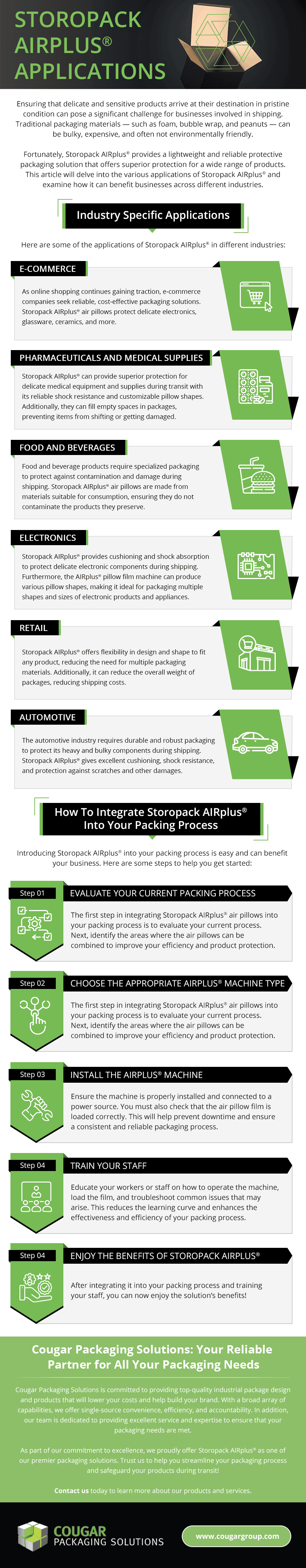

Storopack AIRplus® Applications

Leave a CommentEnsuring that delicate and sensitive products arrive at their destination in pristine condition can pose a significant challenge for businesses involved in shipping. Traditional packaging materials — such as foam, bubble wrap, and peanuts — can be bulky, expensive, and often not environmentally friendly.

Fortunately, Storopack AIRplus® provides a lightweight and reliable protective packaging solution that offers superior protection for a wide range of products. This article will delve into the various applications of Storopack AIRplus® and examine how it can benefit businesses across different industries.

Industry Specific Applications

Here are some of the applications of Storopack AIRplus® in different industries:

1. E-Commerce

As online shopping continues gaining traction, e-commerce companies seek reliable, cost-effective packaging solutions. Storopack AIRplus® air pillows protect delicate electronics, glassware, ceramics, and more.

2. Pharmaceuticals and Medical Supplies

Storopack AIRplus® can provide superior protection for delicate medical equipment and supplies during transit with its reliable shock resistance and customizable pillow shapes. Additionally, they can fill empty spaces in packages, preventing items from shifting or getting damaged.

3. Food and Beverages

Food and beverage products require specialized packaging to protect against contamination and damage during shipping. Storopack AIRplus® air pillows are made from materials suitable for consumption, ensuring they do not contaminate the products they preserve.

4. Electronics

Storopack AIRplus® provides cushioning and shock absorption to protect delicate electronic components during shipping. Furthermore, the AIRplus® pillow film machine can produce various pillow shapes, making it ideal for packaging multiple shapes and sizes of electronic products and appliances.

5. Retail

Storopack AIRplus® offers flexibility in design and shape to fit any product, reducing the need for multiple packaging materials. Additionally, it can reduce the overall weight of packages, reducing shipping costs.

6. Automotive

The automotive industry requires durable and robust packaging to protect its heavy and bulky components during shipping. Storopack AIRplus® gives excellent cushioning, shock resistance, and protection against scratches and other damages.

How To Integrate Storopack AIRplus® Into Your Packing Process

Introducing Storopack AIRplus® into your packing process is easy and can benefit your business. Here are some steps to help you get started:

Step 1: Evaluate Your Current Packing Process

The first step in integrating Storopack AIRplus® air pillows into your packing process is to evaluate your current process. Next, identify the areas where the air pillows can be combined to improve your efficiency and product protection.

Step 2: Choose the Appropriate AIRplus® Machine Type

Storopack offers various machine types for different packaging needs, such as the AIRplus® GTI, AIRplus® Mini, AIRplus® Wrap, and more.

Step 3: Install the AIRplus® Machine

Ensure the machine is properly installed and connected to a power source. You must also check that the air pillow film is loaded correctly. This will help prevent downtime and ensure a consistent and reliable packaging process.

Step 4: Train Your Staff

Educate your workers or staff on how to operate the machine, load the film, and troubleshoot common issues that may arise. This reduces the learning curve and enhances the effectiveness and efficiency of your packing process.

Step 5: Enjoy the Benefits of Storopack AIRplus®

After integrating it into your packing process and training your staff, you can now enjoy the solution’s benefits!

Cougar Packaging Solutions: Your Reliable Partner for All Your Packaging Needs

Cougar Packaging Solutions is committed to providing top-quality industrial package design and products that will lower your costs and help build your brand. With a broad array of capabilities, we offer single-source convenience, efficiency, and accountability. In addition, our team is dedicated to providing excellent service and expertise to ensure that your packaging needs are met.

As part of our commitment to excellence, we proudly offer Storopack AIRplus® as one of our premier packaging solutions. Trust us to help you streamline your packaging process and safeguard your products during transit!

Contact us today to learn more about our products and services.

Key Considerations in Custom Packaging Designs

Leave a CommentProduct packaging goes beyond being a mere container for a product; it can shape consumer perception, differentiate a product from competitors, and enhance customer experience. Thus, it plays a crucial role in the overall success of a product.

Often, packaging is the first point of contact for consumers, providing them with important product information. Hence, the right packaging can capture attention, convey brand messaging, and influence purchasing decisions. Well-designed packaging can create a sense of trust, showcase the product’s value, and ultimately drive sales and brand loyalty.

This blog will help you maximize product appeal by mastering key considerations for custom packaging designs that complement the product and captivate your target audience.

1. Consistency With the Product

Consistency with the product is essential for businesses to maintain a strong brand presence. This involves three key aspects:

- Design and branding: Align marketing materials with the product’s design elements to create a unified and recognizable brand identity.

- Features and benefits: Consistently highlight the product’s unique selling points and advantages to make the product stand out.

- Target audience: Tailor messaging and advertisingto resonate with the preferences and values of the target audience.

2. Functionality and Practicality

Create user-friendly packaging with features like easy opening mechanisms and clear instructions. Moreover, choose materials that offer sufficient protection to ensure the product reaches customers in optimal condition. To enhance usability, you may even incorporate convenient features, such as resealable options or portion control mechanisms. This will differentiate your brand and leave a positive impression on consumers.

3. Visual Appeal and Aesthetics

One way to stand out from competitors is by incorporating unique visual elements. For instance, you can effectively communicate the product’s message using colors, typography, and imagery. These can helpyou can engage consumers, create a positive perception of your product, and increase its chances of being picked from the shelf.

4. Branding and Messaging

Consistency in branding across various product variations unifies the brand’s presence and enhances its impact. In particular, emphasize the brand’s logo, name, and tagline for instant recognition and better recall. Moreover, you can explore ways to communicate the product’s exceptional value proposition with clarity and conviction, captivating and informing consumers effectively.

5. Sustainability and Eco-Friendliness

Your brand’s dedication to environmental responsibility through impactful messaging and visual cues can attract eco-conscious consumers. Thus, embrace eco-friendly materials, prioritize waste reduction, and encourage recyclability.

6. Practical Considerations

Businesses can attain efficient, practical product packaging through cost-effective designs and optimized sizes for transport and storage. Additionally, adhering to regulatory compliance and safety standards is crucial. Considering these will make your brand reduce costs, minimize waste, and enhance customer satisfaction with their products.

7. Consumer Experience

Create a remarkable customer experience through product packaging. For example, you can enhance the unboxing process with thoughtful design elements. Moreover, consider including clear and informative product labels and instructions. By prioritizing these elements, you can leave a lasting impression, foster satisfaction, and build strong customer relationships.

Elevate Your Product Packaging With Cougar Packaging Solutions

Are you ready to take your product packaging to the next level? At Cougar Packaging Solutions, we emphasize custom packaging designs to complement your product and engage your target audience. Whether you need eco-friendly materials or user-friendly features, we’ve got you covered!

Our team of experts is committed to providing exceptional products and services that align with your brand’s values and goals. Our 50 years of industrial packaging experience have also allowed us to acquire deep and broad problem-solving expertise to deliver excellent, cost-effective packaging solutions.

Contact us today to learn how we can help you elevate your product packaging and be a total stand-out!

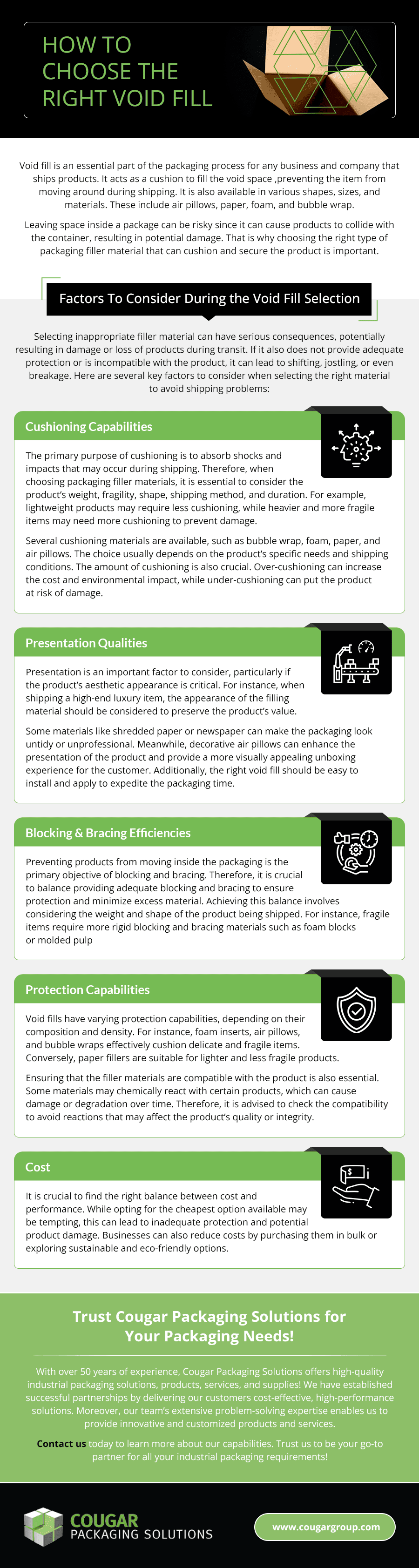

How To Choose the Right Void Fill

Leave a CommentVoid fill is an essential part of the packaging process for any business and company that ships products. It acts as a cushion to fill the void space ,preventing the item from moving around during shipping. It is also available in various shapes, sizes, and materials. These include air pillows, paper, foam, and bubble wrap.

Leaving space inside a package can be risky since it can cause products to collide with the container, resulting in potential damage. That is why choosing the right type of packaging filler material that can cushion and secure the product is important. In this article, we will present key factors to consider when selecting the right type of void fill for your application.

Factors To Consider During the Void Fill Selection

Selecting inappropriate filler material can have serious consequences, potentially resulting in damage or loss of products during transit. If it also does not provide adequate protection or is incompatible with the product, it can lead to shifting, jostling, or even breakage. Here are several key factors to consider when selecting the right material to avoid shipping problems:

Cushioning Capabilities

The primary purpose of cushioning is to absorb shocks and impacts that may occur during shipping. Therefore, when choosing packaging filler materials, it is essential to consider the product’s weight, fragility, shape, shipping method, and duration. For example, lightweight products may require less cushioning, while heavier and more fragile items may need more cushioning to prevent damage.

Several cushioning materials are available, such as bubble wrap, foam, paper, and air pillows. The choice usually depends on the product’s specific needs and shipping conditions. The amount of cushioning is also crucial. Over-cushioning can increase the cost and environmental impact, while under-cushioning can put the product at risk of damage.

Presentation Qualities

Presentation is an important factor to consider, particularly if the product’s aesthetic appearance is critical. For instance, when shipping a high-end luxury item, the appearance of the filling material should be considered to preserve the product’s value.

Some materials like shredded paper or newspaper can make the packaging look untidy or unprofessional. Meanwhile, decorative air pillows can enhance the presentation of the product and provide a more visually appealing unboxing experience for the customer. Additionally, the right void fill should be easy to install and apply to expedite the packaging time.

Blocking and Bracing Efficiencies

Preventing products from moving inside the packaging is the primary objective of blocking and bracing. Therefore, it is crucial to balance providing adequate blocking and bracing to ensure protection and minimize excess material. Achieving this balance involves considering the weight and shape of the product being shipped. For instance, fragile items require more rigid blocking and bracing materials such as foam blocks or molded pulp.

Protection Capabilities

Void fills have varying protection capabilities, depending on their composition and density. For instance, foam inserts, air pillows, and bubble wraps effectively cushion delicate and fragile items. Conversely, paper fillers are suitable for lighter and less fragile products.

Ensuring that the filler materials are compatible with the product is also essential. Some materials may chemically react with certain products, which can cause damage or degradation over time. Therefore, it is advised to check the compatibility to avoid reactions that may affect the product’s quality or integrity.

Cost

It is crucial to find the right balance between cost and performance. While opting for the cheapest option available may be tempting, this can lead to inadequate protection and potential product damage. Businesses can also reduce costs by purchasing them in bulk or exploring sustainable and eco-friendly options.

Trust Cougar Packaging Solutions for Your Packaging Needs!

With over 50 years of experience, Cougar Packaging Solutions offers high-quality industrial packaging solutions, products, services, and supplies! We have established successful partnerships by delivering our customers cost-effective, high-performance solutions. Moreover, our team’s extensive problem-solving expertise enables us to provide innovative and customized products and services.

Contact us today to learn more about our capabilities. Trust us to be your go-to partner for all your industrial packaging requirements!