In supply chain management and logistics, packaging is one of the key components to ensure the safe delivery of products. It protects the goods from damage during transportation and is vital in keeping the product presentable to customers.

There are two main types of packaging: protective packaging and void fill packaging. Protective packaging safeguards the product from external factors such as impact, vibration, and compression. Conversely, void fill packaging occupies empty spaces in parcels to prevent product movement during transportation.

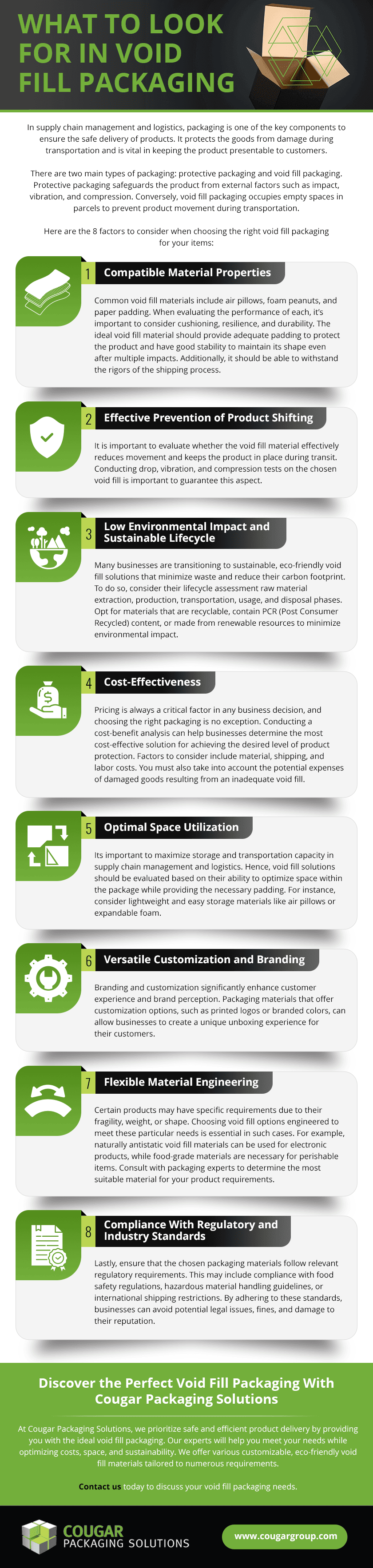

Here are the 8 factors to consider when choosing the right void fill packaging for your items:

1. Compatible Material Properties

Common void fill materials include air pillows, foam peanuts, and paper padding. When evaluating the performance of each, it’s important to consider cushioning, resilience, and durability. The ideal void fill material should provide adequate padding to protect the product and have good stability to maintain its shape even after multiple impacts. Additionally, it should be able to withstand the rigors of the shipping process.

2. Effective Prevention of Product Shifting

It is important to evaluate whether the void fill material effectively reduces movement and keeps the product in place during transit. Conducting drop, vibration, and compression tests on the chosen void fill is important to guarantee this aspect.

3. Low Environmental Impact and Sustainable Lifecycle

Many businesses are transitioning to sustainable, eco-friendly void fill solutions that minimize waste and reduce their carbon footprint. To do so, consider their lifecycle assessment raw material extraction, production, transportation, usage, and disposal phases. Opt for materials that are recyclable, contain PCR (Post Consumer Recycled) content, or made from renewable resources to minimize environmental impact.

4. Cost-Effectiveness

Pricing is always a critical factor in any business decision, and choosing the right packaging is no exception. Conducting a cost-benefit analysis can help businesses determine the most cost-effective solution for achieving the desired level of product protection. Factors to consider include material, shipping, and labor costs. You must also take into account the potential expenses of damaged goods resulting from an inadequate void fill.

5. Optimal Space Utilization

Its important to maximize storage and transportation capacity in supply chain management and logistics. Hence, void fill solutions should be evaluated based on their ability to optimize space within the package while providing the necessary padding. For instance, consider lightweight and easy storage materials like air pillows or expandable foam.

6. Versatile Customization and Branding

Branding and customization significantly enhance customer experience and brand perception. Packaging materials that offer customization options, such as printed logos or branded colors, can allow businesses to create a unique unboxing experience for their customers.

7. Flexible Material Engineering

Certain products may have specific requirements due to their fragility, weight, or shape. Choosing void fill options engineered to meet these particular needs is essential in such cases. For example, naturally antistatic void fill materials can be used for electronic products, while food-grade materials are necessary for perishable items. Consult with packaging experts to determine the most suitable material for your product requirements.

8. Compliance With Regulatory and Industry Standards

Lastly, ensure that the chosen packaging materials follow relevant regulatory requirements. This may include compliance with food safety regulations, hazardous material handling guidelines, or international shipping restrictions. By adhering to these standards, businesses can avoid potential legal issues, fines, and damage to their reputation.

Discover the Perfect Void Fill Packaging With Cougar Packaging Solutions

At Cougar Packaging Solutions, we prioritize safe and efficient product delivery by providing you with the ideal void fill packaging. Our experts will help you meet your needs while optimizing costs, space, and sustainability. We offer various customizable, eco-friendly void fill materials tailored to numerous requirements.

Contact us today to discuss your void fill packaging needs.